Call

+48 504 196 988

+48 504 196 988

QUALITY CONTROL FOR CNC MILLING AND TURNING SERVICES

Quality Control – its task is to supply fully compliant elements, eliminate shortages and raise customer satisfaction. Tools used for quality control are the following:

Hand measuring tools – instruments used to measure external and internal dimensions, most often used both at the machine and quality control stand. The hand tools are the following:

– thread and hole checks

– slide calipers

– micrometers

– bar gauges

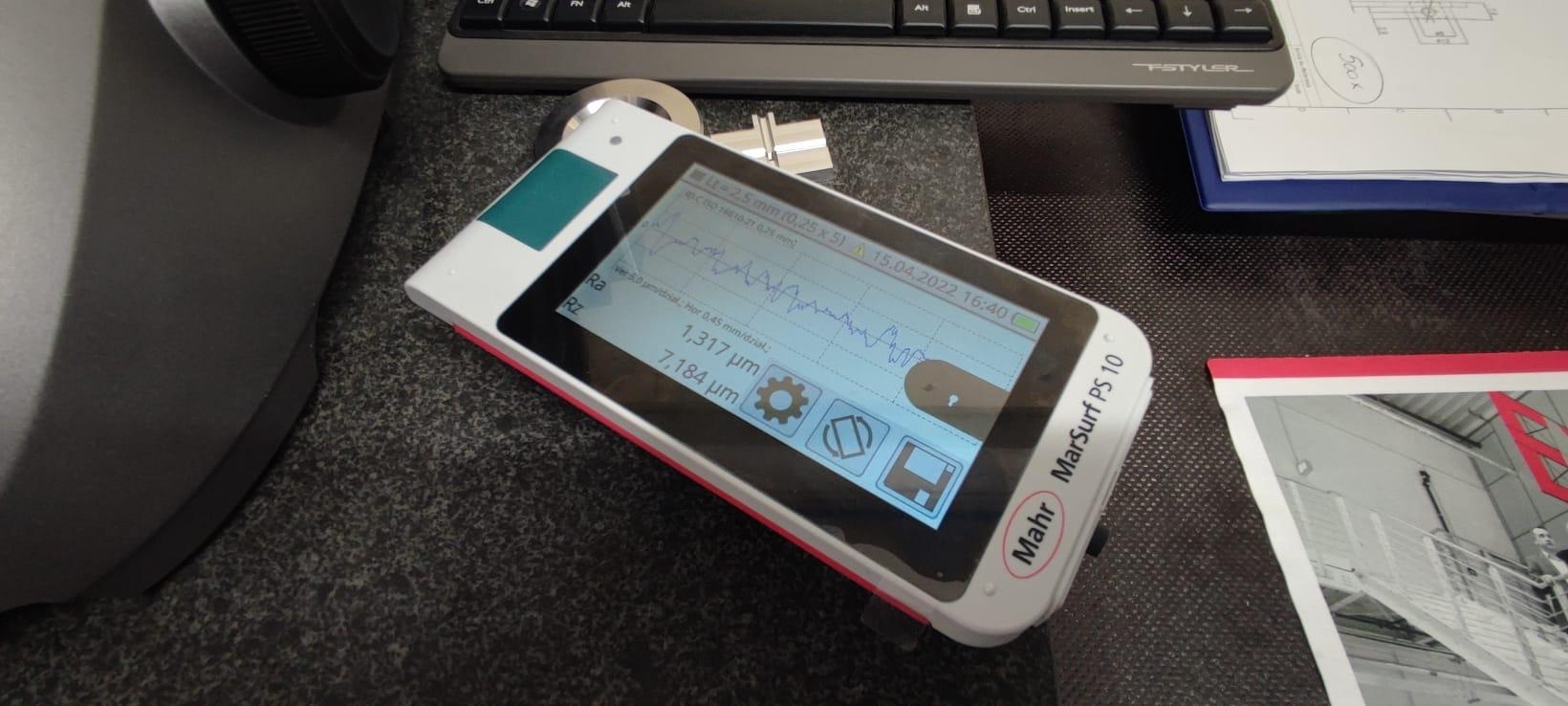

– roughness meters

The precision obtained in these tools is around 1 micrometer (+/- 1um), that is a thousandth of millimeter (0.001 mm).

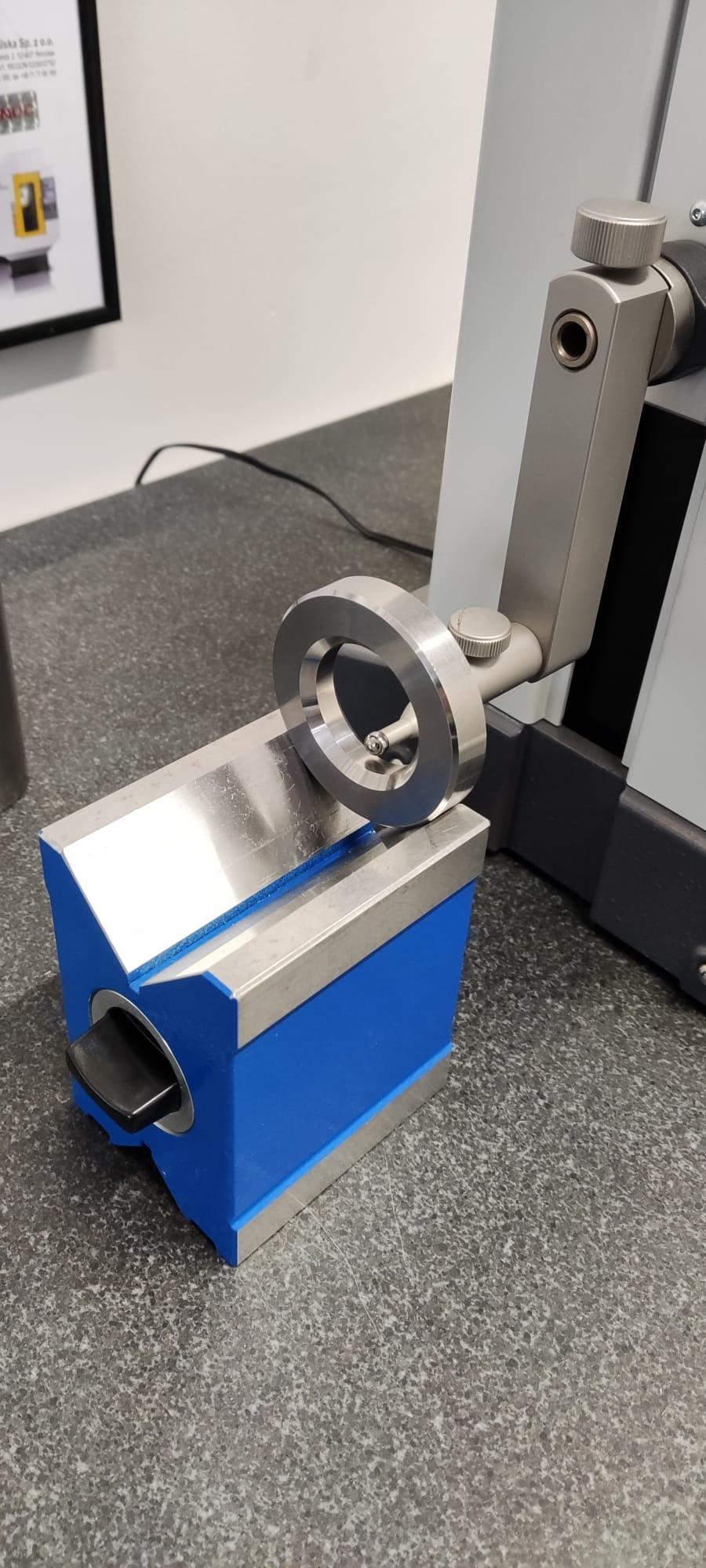

Automated measurement tools – they allow specifying mechanical sizes in the automatic cycle, assuring high accuracy (minor error) and high repeatability. The examples of such devices are the following:

– coordinate machine, accuracy of the measurement up to 1 um

– altimeter, accuracy of the measurement up to 1um (see photo of the MAHR altimeter on the right)

Projection gauges – can be divided into manual and automatic. These days a modern CNC milling and turning company (specializing in a widely understood machining) must be in possession of fast, reliable and precise measuring instruments. Automatic projection gauges belong to this group.

The element manufactured on the basis of machining or service measurement can be measured through its shadow projection. Using the modern optical system and diverse external or internal lighting, we can use SCALMAX projectors to measure up to 200 different dimensions, such as length, width, hole diameters, thread pitch, aligning, roundness, centricity and many other in a couple of seconds, with an accuracy of up to 0.005 mm and repeatability of 2um. A modern high-series production company that relies on CNC machining cannot do without this device. The example of our machine is the Keyence IM6225 projection gauge (see photo below). Additionally, the use of the projection gauge for the purposes of quality control lets you generate the measuring report (no need to do so manually) for a specific part. The device is capable of specifying whether any of the dimensions is non-conforming, and if so – which one. The Keyence projector is able to generate the advanced quality report and can automatically specify coefficients: 3σ (3 sigma), 6σ (6 sigma).

+48 504 196 988

+48 504 196 988 info@cnc-poland.eu

info@cnc-poland.eu